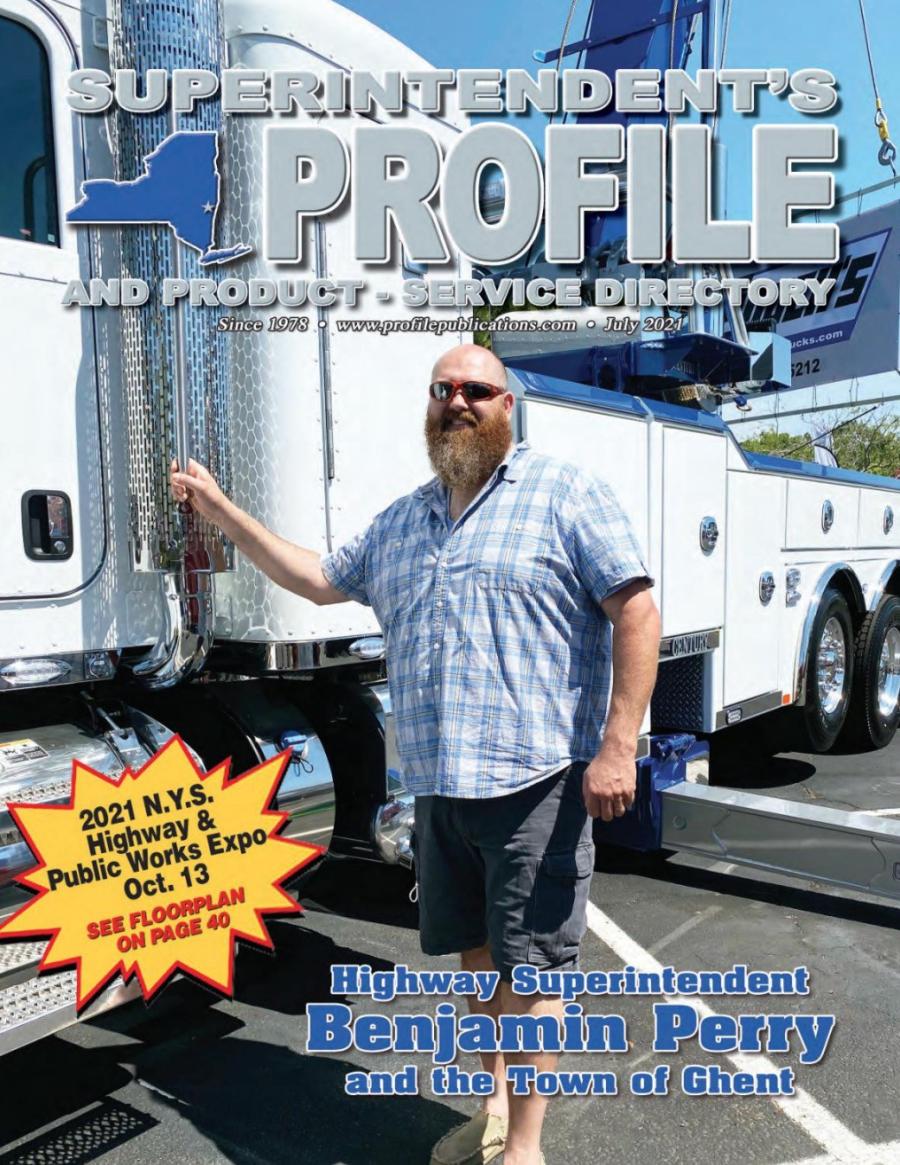

Highway Superintendent Benjamin Perry and the Town of Ghent

Lori Lovely – PROFILE CORRESPONDENT - July 2021

When a town elects a mechanic to serve as its highway superintendent, it should come as no surprise that equipment and fleet maintenance become top priorities.

"The town board has worked with me very well in understanding my main goal of maintenance," said Benjamin Perry, the town of Ghent's youngest highway superintendent in 2014 — and one of the youngest in the entire state.

Benjamin was just 33 years old when then-Highway Superintendent Mike Losa, who was retiring, and former Town Supervisor Larry Andrews approached him about running for the office. "I never thought I could or would do this type of job," Benjamin said. "I was very hesitant to accept."

In fact, he turned down the job in 2009 to work for the town as head mechanic. He had been working in the same position for Mack Truck; that job paid well, making it difficult to leave.

"I set my price," he said, knowing he had the skills, experience and ability to "take the town to a whole new level of capability."

Eventually, he got his price and Ghent got a new, promising employee who was focused on the fleet. That's not to say he was a spendthrift. Benjamin used his mechanical skills and his wiles to get or make the best fleet possible.

Old, New: Managing the Fleet

Benjamin set to work immediately, deciding which equipment was good enough to keep, what had run its course of lifetime usefulness, what needed some work and what pieces of equipment the town was missing.

In 2017, he worked with his accountancy firm to put together a 10-year financial plan that would enable the town to purchase some new equipment and a used tractor trailer.

"We took out a $530,000 note for a new loader, mini-excavator, two Dodge 5500 dump trucks, fully equipped, built in-house for a cost savings of $30,000, as well as a used tractor trailer and tri-axle dump trailer," he said. Ghent is the only town in Columbia County that owns a tractor trailer with dump trailer, he pointed out.

The savvy superintendent estimated that the tractor trailer saves the town $60,000 per year in trucking costs — which ends up paying for the note. The savings is written into the annual budget, so the purchases don't cost the taxpayers anything out of pocket.

"This also allows me to have a very healthy fund balance account, just in case anything unexpectedly happens to the highway or any equipment."

The following year, Benjamin attained a state grant for $75,000 through State Senator Kathy Marchione. State senators have access to certain state grants that offer financial assistance to organizations in their districts. She was key in aiding Benjamin to obtain a grant for the town of Ghent.

Like the CHIPS program, Ghent had to put up money before the state reimbursed it, but this grant allowed Benjamin to build a complete pickup setup for his work truck, complete with plow, sander, lighting and radio equipment — and $10,000 to spare. Because the state informed him that he had to spend the money, he purchased an Everest Vortex four-way plow for a large truck. By following the state grant guidelines, he acquired new equipment without costing the taxpayers anything.

He's also been rebuilding the fleet of trucks, upgrading only what is absolutely necessary.

"New is not always better," said the former mechanic. "I hear horror stories regarding new plow trucks being down [instead of] out working like they should be."

Besides, today's technology is so advanced, it requires special tools to work on equipment — and that's not in the budget.

"We just don't have the tools or the money to buy new all the time," he said, adding that a new 10-wheel plow dump truck costs about $250,000.

That's why he's upgrading one of their oldest plow truck dump bodies. The 1998 truck will be getting upfitted with a new $43,000 all-season stainless steel Everest dump body, which Benjamin calculates will give them another 10 years before the body goes to another chassis.

"This will be the fourth body swap we have done in the last seven years with other rebuilds to other trucks."

In addition to rehabbing 95 percent of their fleet in-house, Benjamin and his crew have built trucks from the ground-up, saving the town considerable money.

"We have rehabbed [more than] 11 major pieces of equipment in the 13 years I've been with the town," he said. "Maintenance, maintenance and more preventative maintenance will get every penny out of our investments, and still have good resale value."

Maintenance Schedule

Before each season, Benjamin's mechanics go through all the equipment to prepare it for what's ahead. Many of their trucks are multi-use vehicles — like the dump truck that can be converted from winter use to hauling dirt, blacktop or chip stone or towing equipment.

Making maintenance easier, Benjamin and his crew work out of one of the largest town garages in the area: a 150-ft. by 80-ft. building constructed in 2009 for just under $1 million, due to town employees doing a lot of the work.

Its 80-ft. by 100-ft. main section with 35-ft. ceilings houses 20 pieces of large primary-use equipment during the winter.

"Our facility is big enough that we can fit all the equipment inside," Benjamin said.

The rest of the building features two offices, two bathrooms, a large breakroom with full kitchen for overnight winter storm stays and an 80-ft. by 25-ft. two-bay repair shop.

Having such a big facility enables him to sustain a rigorous maintenance schedule.

"It allows us to do more in-house work. In the 13 years I have been with the town, we have only sent equipment out to be repaired three times," Benjamin said, proudly.

Those three times occurred because he didn't have the proper tools for the job and decided it was more cost-effective to send the equipment out for repair than invest in tools for a one-time job.

He does keep a large number of parts on hand for everyday breakdowns and said he and his crew can get most back up and running within hours, keeping downtime to the bare minimum. But when time is of the essence — especially during a winter storm — he doesn't waste time on repairs. He has a backup plan.

"We have three spare plow trucks," Benjamin said.

There's a 4900 International with a gondola sander fully set up with plow and wing, ready for plowing when needed, and there are two 2017 Dodge 5500 all-season dump bodies with four-way poly plows. If they can't fix a minor problem between rounds of plowing, they'll park a unit and grab another to finish their eight plow routes, each of which takes about 2.5 hours to complete, saving the repair for later.

Four International 4900 plow trucks date back to 1996, 1998, 2000 and 2002, each with more than 100,000 miles on it. There are also two 2007 Mack Cv 713 plow trucks, a 2014 Mack GU713 plow truck, a 2014 utility body plow truck, a 2011 GMC 2500HD pickup plow truck and a 2018 Dodge 3500 pickup plow truck.

The town owns all its equipment. Other equipment in Ghent's inventory includes:

- 2005 International 9500i tractor trailer

- 2000 GMC 3500 bucket truck

- 1987 Caterpillar loader 938

- 2017 Volvo L90 loader

- 2005 Case excavator CX130

- 2017 Kubota excavator K57

- 2009 John Deere 325 skid steer

- 1980 Fiat Allis 85 grader

- 12-ton Bomag roller

- 4-in. Gorman Rupp diesel water pump

- John Deere 6230 roadside mower tractor

- John Deere 1445 park mower

- 2005 Benson dump trailer, 34.5-ton capability

- 1980 20-ton tag trailer

- 2005 20-ton Big Tow equipment trailer

- 2014 12-ton b-Wise tilt-deck trailer

- 2020 4-ton custom-built in-house leaf vac trailer

"We might have some older equipment," Benjamin said, "but you would not know it, the way we keep up on these units."

Each year, they choose a machine or two to "strip to the bare bones and rehab, going through everything from one end to the other and back again."

They're so thorough, they rarely experience equipment failures. A 1998 International they rebuilt in 2014 just had its first hydraulic hose leak. Benjamin said his crew was able to fix the issue with supplies that were on hand.

"We are fully equipped with a hydraulic press to make our own hoses in-house."

Teamwork Makes the Dream Work

Getting high marks from the town supervisor indicates what an effective job Benjamin does.

"In 40 years of public service, I have found Ben Perry to be a valuable asset," said Mike Benvenuto, "and certainly one of the best that I have had the honor to work with. Ben cares about what he does. He spends a lot of time thinking about his job, how he handles his employees and what projects he needs to perform."

Part of that thinking has resulted in Benjamin surrounding himself with good people who make his job easier. He oversees an eight-man full-time crew consisting of:

- William Ordway, foreman

- Peter Everett, senior automotive mechanic

- Aaron Lindop-Braun, highway equipment maintenance mechanic

- Joshua Ordway, senior motor equipment operator

- Vince Gerber, motor equipment operator

- Danny Lamarre, motor equipment operator

- Jonathan Mena, motor equipment operator

- William Weaver, motor equipment operator

His head mechanic, Aaron Lindop-Braun, stays in the shop 95 percent of the time, lending a hand with plowing during large storms. The other full-time mechanic, Peter Everett, who has been with the town 17 years, floats between the shop and the field to help with whatever is needed to get the job done. "He is a real asset," Benjamin said.

William Ordway, who has worked for the town for 27 years under the two previous superintendents, is Benjamin's go-to guy. "Knowing someone has working knowledge of the operation is a real help," Benjamin said.

The feeling is mutual. Ordway said the boss listens to suggestions and spends considerable time training the crew. "It's truly nice to have the right tools for the job," he said.

"If you need a tool for a job, he's very understanding as to why you are asking for tools," Lindop-Braun added. "He makes sure we have everything we need to do the job right."

New to the staff, Lindop-Braun was hired after another mechanic who had been with the crew for seven years left to start his own mobile repair business.

"I overheard the then-head mechanic talking to my new mechanic one day about making sure he knows what I expect. He said it's been pretty good to work for a boss who has done this job before. The boss knows everything about this job."

Benjamin's motto is to work smarter, not harder, and he takes pride in his equipment fleet, knowing that if it's in good condition, his crew is safer and able to do a better job. He's also open to suggestions.

"If someone has an idea, I'm always open to improvement for efficiency and safety."

Creative Crew

His crew often does have ideas.

"It's not always about me," Benjamin said. "I'm willing to try things. My crew can be pretty creative. We're always fabricating something to make things better."

Benjamin observed that they have similar issues as other towns.

One of those issues is a mammal: beavers — the "best engineers on earth, bar none, they are," he said.

They struggled for years with beavers on one particular section of road. The crew collaborated on an innovation by extending pipe out 10 ft. and drilling 30 two-in. holes in the bottom of the pipe set post in the pond, with a gate over the ends. He said the beavers can't figure out where the water is going without the sound of rushing water, so the pond remains at a consistent water level: no more blockages and no more flooding. "We have not had one plugged pipe in almost three years."

To simplify cleaning ditches and make pipes easier to maintain, the crew devised a custom-built leaf vac trailer. They once again put their heads together to build a 10-ft. adjustable blacktop drag that allows them to patch an entire road in just two passes. It takes the whole crew, Benjamin said. The driver who can maintain a straight line, ground guys, two box operators, a roller man and flaggers. Nevertheless, he said, it's an improvement over using a grader, which wasn't laying the material evenly and ended up wasting a lot of it.

Two part-timers help flag on major paving jobs, as does another part-time person, Daniel Kennedy, a retired tree cutter, who also runs the road mower.

He's currently working with Trout Unlimited and the Department of Environmental Conversation on a fresh water crossing culvert system. The two organizations work with the town through this program to highlight problem areas for water life and other issues for the town's waterway system, such as flood areas.

Winter hours from November to March are 7 a.m. to 3:30 p.m., five days a week. Summer hours from April through October are 6 a.m. to 4:30 p.m., four days a week. However, Benjamin doesn't keep strict office hours. He puts in more hours than he records, as his wife, Rachel, who runs one of the largest daycare/learning centers in the county, can attest to. "She has spent a lot of nights home alone with our daughters," he said. "I'll get a call and it's ‘I gotta' go. See you later.' And out the door I go."

Overseeing Things

Once out the door, there's a lot for Benjamin to manage. As much as he makes equipment a top priority, he also focuses on the roads, to which he applies an equally rigorous maintenance schedule. He and his crew maintain 142.2 lane miles of roads and streets — of which, 137.42 are paved, leaving less than 5 miles of gravel roads — and four owned bridges.

"Drainage, drainage, drainage," he said. Good drainage contributes to better infrastructure. "If water is on the road or sitting next to it, that's just not good."

A tactic Benjamin likes to use is to place small crews on multiple jobs around the town.

"You get more done if you spread out," he said. It doesn't work for every job; in fact, some jobs require additional assistance from other towns.

Ghent has a shared service agreement with the other towns in Columbia County and the State Department of Transportation to ease the burden somewhat.

"We could never get all of our paving projects done without a shared service agreement in place," Benjamin said.

More than once he's had 20 or more employees from other towns help on a paving project.

"We average around 20 miles of paving and sealing roads a year. It takes a lot of organization to make this happen. We spend big money in just a few days, so the extra hands help greatly."

The town's annual operating budget of $1.3 million and a CHIPS allocation of $212,000 is a substantial budget. But, as his wife observed, Benjamin is "incredibly conscientious about how he spends the money in his budget, always making sure to do his research and due diligence."

Benjamin relies in part on his experience running a truck shop as a profitable business. He knows where to save and where to spend. Tight control over the budget — pinching pennies when necessary and spending money where justifiable — enabled him to purchase a tool to put on the excavator to clean out pipes. Having seen ads for the clog cleaner, he ordered it from Arkansas and surprised his crew.

Splurges like that are carefully calculated. "I've never gone over budget," he said.

Knowing he would have to answer to auditors if he did, he added, "I know where the dollars and cents are."

As the town supervisor, Mike Benvenuto said he worries about the budget every month. But one department that doesn't give him any concern is the highway department.

"I know like clockwork that Ben will either cover his budget to the penny or more likely save in spending to be able to utilize that budgeted money for something the department might need or another project that might be important."

Helping keep his numbers — and his office — in check is part-time secretary Wendy Shufelt. "Not one penny will get by this guy," she said. "He has a hawk eye for tax dollars."

One example of their meticulous budgeting is the Angel Hill Road full bridge replacement project, their biggest project to date. Never having built a bridge didn't faze Benjamin. Walking with confidence, he did his homework and asked questions. "I have been involved in some projects," he said, "but nothing like this."

He contacted the right people, and they guided him well. Once he had completed his research, he met with the county's engineering department and Barton & Loguidice Engineering to discuss what he hoped to do and how to save money. "My goal was not to have to touch the streambed at all," he said.

They achieved his goal by building behind the old sheet pilons without disturbing the streambed. Instead of pouring concrete, they built a geosynthetic block system and hand-laid the blocks. The only work Benjamin had to hire out was a crane to place the bridge decking and a company to pound the post in for the rails. Doing most of the work in-house turned a $250,000 job into a $97,000 one. He credited savings like that as the reason he's earned the respect of the town board.

"Getting equipment or the right tool to do the job has never been an issue," he said.

Much of that equipment is stored with other supplies in a 100-ft. by 40-ft. cold storage building. They also have a main building, built in 2009, and a salt shed they co-own 60/40 with the county since the early 2000s. Divided internally, the shed holds approximately 5,000 tons of mixed material and 500 tons of straight salt — with "room to move a little bit," Benjamin said.

It also features a lean-to that runs the entire length of the building, for added storage.

Community Outreach, Communication

Keeping records and keeping in touch with his crew, his community and nearby towns are important aspects of Benjamin's job. For the former, he uses a Blue Point for diagnostics on the equipment and an office computer and an iPad for documenting highway work. With his crew and neighboring towns, law enforcement and fire departments, he uses a high-band radio system.

When it comes to the community, he takes a more hands-on approach, actually knocking on doors to let residents know why they're working in the area.

"I have spent countless hours out doing public relations," he said.

Time spent updating the public about upcoming work alleviates many unhappy phone calls later from residents inquiring about crews working in their neighborhoods.

But his community involvement goes much further. Benjamin sits on the Board of Traffic Safety for Columbia County and attends the annual Advocacy Day, where he speaks with senators representing all 21 municipalities in the county about the CHIPS program and other pertinent issues.

He represents those 21 municipalities as president of the Columbia County Association of Town Superintendents of Highways, another elected position, which he has held for eight years.

"Every highway superintendent during my first year as highway superintendent, including the county highway superintendent voted without ever asking me if I wanted it," Benjamin said.

They told him they voted for him because they'd never met someone more respected or more of a true leader than he is. "I was blown away."

As president of the association, Benjamin hosts an annual equipment show at Ghent's garage. The show accommodates about 25 vendors, such as parts suppliers, lubricant companies, paving companies, highway safety suppliers, and trucking, heavy equipment and body and plow manufacturers, with around 40 pieces of equipment on display.

"It's a great way for the sales reps to see everyone at once," he said, estimating a crowd of 200 or more from neighboring towns and counties.

He's been invited to the schools to do presentations at the local middle school on Career Day. In addition, he welcomes field trips, allowing students to tour the highway department. It's an example of the rapport he has with the residents, as well as local contractors, law enforcement and other DPWs.

Something Different Every Day

Benjamin wears many hats in his role as superintendent. "I really enjoy the diversity of the job," he said. "You never know what the day will bring you."

His best day on the job took him to Canada to meet with the head engineers, sales team and president of Everest to discuss his ideas of how they could better engineer their products to respond to the industry's needs.

"It was one of my most honored moments," he said, recalling how one of the biggest companies in the industry sought his opinion, knowing not every mechanic gets a personal invitation to such a sit-down.

They talked about how he used their products, not realizing how many uses he put their equipment to. They even followed up months later to get additional detail.

It's not unusual for people to seek Benjamin's advice.

"I get calls all the time from other highway superintendents, asking what I think or how do I spec out a piece of equipment," he said.

His contemporaries are aware of his experience as a truck builder who, although he's now superintendent, still turns a wrench.

Sadly, his worst day on the job followed shortly after this heady once-in-a-lifetime experience. The day after he returned from his visit with Everest, a phone call came from a friend who had helped arrange his trip to Canada. The head salesman, a friend, had passed away on the return trip.

"After spending a couple of days together, having breakfast the last morning, we were to head back to the States," Benjamin said. "On his trip back home, he had a massive heart attack."

Crushed by the loss of his friend, the superintendent was surprised by the suddenness of it all.

"We had a great time. Never expected anything," he said. "To get that call … it really hit hard. It just shows, you never know what life will bring you."

Benjamin, always a man with a positive can-do attitude, said this experience increased his passion to help others and continue sharing his knowledge and setting the bar.

He has established a work ethic and level of craftsmanship, setting an example by working at the highest level of professionalism, which he now expects out of his crew.

"I don't take this job lightly," he said, pointing out that he keeps the town's and the taxpayers' best interests in mind at all times. Mike Benvenuto commended his professionalism on the job.

"He does it all: field training for crew members, working alongside them, leading by example. He literally and figuratively wears a lot of hats, keeping a collection in his office," he said.

"Ben is an incredibly hard-working man," Rachel said. "[He] works hard to keep the town roads safe for the people."

In the seven years since Benjamin took the job, he and his crew have redone 80 percent of the road system, according to Ordway. "This has been the most rigorous planning the town has ever seen."

The community has taken notice and expresses its appreciation. "It is really nice to get compliments, knowing we are part of his vision to make the highway better."

He Chose a Career

Benjamin said he never imagined being in the position he has held since 2014.

"I kept telling them I am not a political person at all," he said. "I am a working man and I have a young family."

Once he'd been convinced that the town didn't need a politician for a superintendent, he started realizing he had the skills necessary to get the job done.

Before working as the town mechanic, Benjamin was head mechanic for a division of Mack Trucks in Albany, N.Y., where he served as an alignment specialist and truck builder. His background is in farming, landscaping, mechanics and management, but he may have been inspired by his grandfather, who was the head mechanic for US Airlines in Boston.

During his high school years, Benjamin attended Quest Star for automotive repair. Finding his niche there turned things around for a struggling student.

"I was even allowed to do a work-study program during my senior year at an Ag dealership," he said.

His grades reached their highest level while he was working on equipment in that program.

After high school, he attended Wyoming Tech College, taking part in a program for diesel engines. He graduated at the top of his class. His skills were recognized at that early stage; he fielded job offers from around the country.

But he chose to return to New York. His love for his hometown as well as big iron and powerful trucks led to a job with a logging equipment dealership. "After being away from home, I changed gears to over-the-road trucks," Benjamin said.

Ghent, a small, scenic town of approximately 5,400 residents, is located in Columbia County in the idyllic Hudson Valley of upstate New York. White settlers took over areas already cleared by Native Americans around 1735 and eventually formed the town from parts of others: namely, Chatham, Claverack and Kinderhook.

Named for its sister city in Belgium, Ghent is home to the historic Van Valkenburgh-Isbister Farm, established in 1790. Listed on the National Register of Historic Places, the farm complex includes an 18th century barn, stable, carriage barn, smoke house and wagon sheds, as well as other buildings, and is a beloved tourist attraction.

Benjamin enjoys his hometown's natural offerings and likes to hunt and fish. He and his wife also like taking their two daughters, Hailey, 15, and Cheyanne, 13, camping in the lush state campgrounds that are so plentiful in the state.

He grew up here. He got married here 19 years ago. He started a family here. An active church member, Benjamin has coached little league, girls' softball and his kids' soccer team, filling in when their team needed a referee. "The one great thing about being the boss is that I have never missed a single game I told them I would be there for," he said.

The busy superintendent has a second job, working nights and weekends as a mechanic, truck driver and operator for a local construction contractor for the past 18 years.

"It has truly helped me in my position as highway superintendent," he said, although he admitted the schedule can be a "real juggle." Fortunately, he said the contractor understands that the town's needs come first. "My phone rings, and I am gone to deal with whatever comes my way."

Running for Office

He hopes to continue dealing with town issues after his current term expires this year; he plans to run again. As with his previous two campaigns, he'll be running unopposed and with the backing of all political parties. "I am a working man, not a politician, and that's how I run for this elected position."

Rachel supports him. Benjamin calls her his biggest supporter and his driving force to be better. "I have had her in my corner from the beginning," he said, acknowledging her contributions to his career by understanding the job's demands on his time.

"I cannot predict tomorrow," he said. "Nor do I want to."

Instead, he plans to keep doing what he's been doing every day: work for the people of Ghent. All his predecessors retired, but he's still making this his career and hopes to run again, unopposed.

When he was nine years old, his grandfather told him that if he was good at what he does, he won't have to tell anyone because they'll tell him. The town asked him to run for office because they saw that he was good at what he'd been doing and they wanted him to do that for Ghent. "I didn't know everything when I started," he said. "I still don't, but I do a ton of research." P